Motors#

One of the many fun things about embedded computers is that you can move physical things with motors.

But there are so many different kinds of motors (servo, stepper, DC), so how do you select the right one?

The type of motor you use depends on the type of motion you want:

- R/C or hobby servo motor

Can be quickly positioned at various absolute angles, but some don’t spin. In fact, many can turn only about 180{deg}.

- Stepper motor

Spins and can also rotate in precise relative angles, such as turning 45°. Stepper motors come in two types:

bipolar(which has four wires) andunipolar(which has five or six wires).

- DC motor

Spins either clockwise or counter-clockwise and can have the greatest speed of the three. But a DC motor can’t easily be made to turn to a given angle.

When you know which type of motor to use, interfacing is easy. This chapter shows how to interface with each of these motors.

Note

Motors come in many sizes and types. This chapter presents some of the more popular types and shows how they can interface easily to the Bone. If you need to turn on and off a 120 V motor, consider using something like the PowerSwitch presented in Toggling a High-Voltage External Device.

Note

The Bone has built-in 3.3 V and 5 V supplies, which can supply enough current to drive some small motors. Many motors, however, draw enough current that an external power supply is needed. Therefore, an external 5 V power supply is listed as optional in many of the recipes.

Note

All the examples in the book assume you have cloned the Cookbook repository on git.beagleboard.org. Go here Cloning the Cookbook Repository for instructions.

Controlling a Servo Motor#

Problem#

You want to use BeagleBone to control the absolute position of a servo motor.

Solution#

We’ll use the pulse width modulation (PWM) hardware of the Bone to control a servo motor.

To make the recipe, you will need:

Servo motor.

Breadboard and jumper wires.

1 kΩ resistor (optional)

5 V power supply (optional)

The 1 kΩ resistor isn’t required, but it provides some protection to the general-purpose input/output (GPIO) pin in case the servo fails and draws a large current.

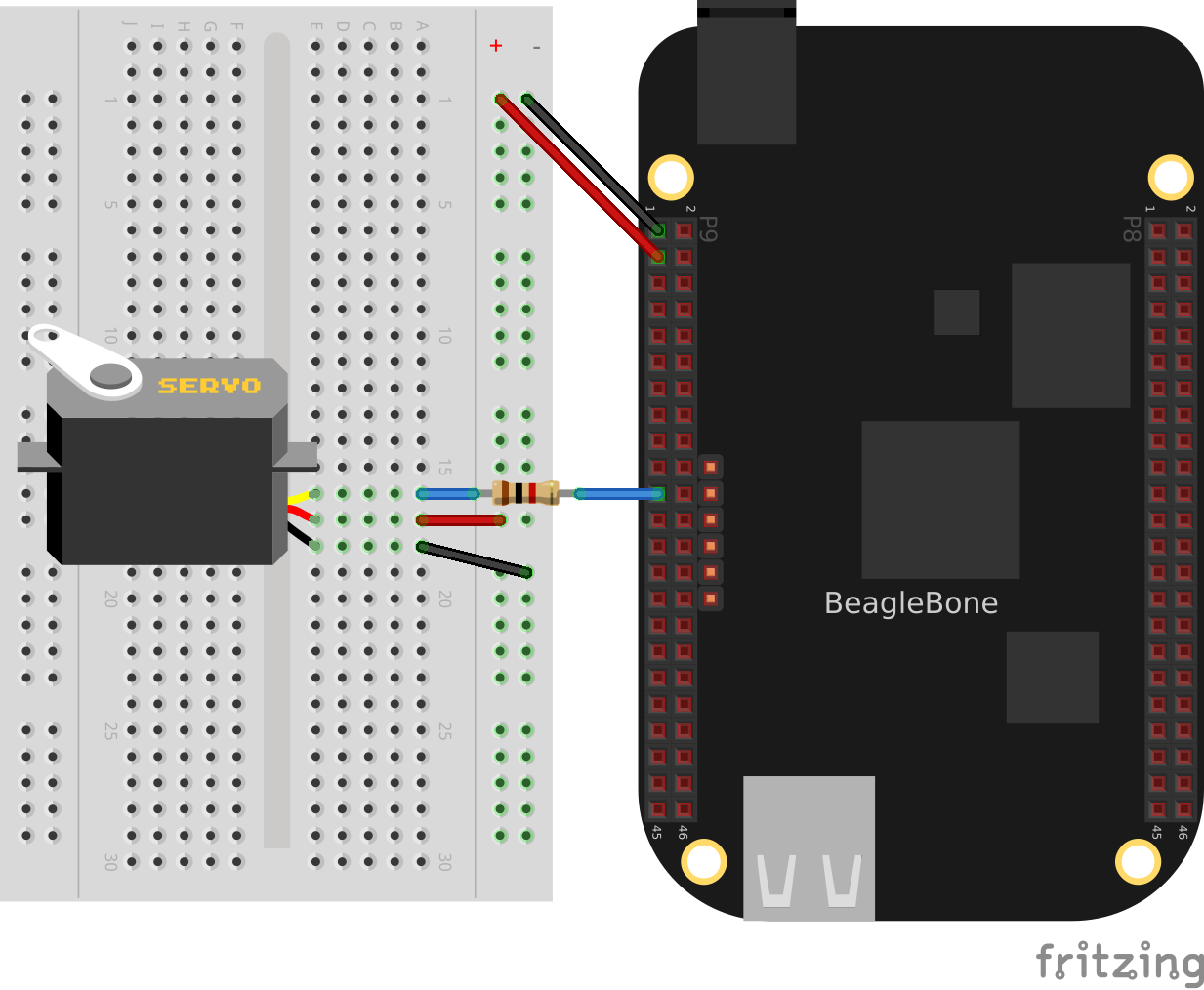

Wire up your servo, as shown in Driving a servo motor with the 3.3 V power supply.

Note

There is no standard for how servo motor wires are colored. One of my servos is wired like Driving a servo motor with the 3.3 V power supply red is 3.3 V, black is ground, and yellow is the control line. I have another servo that has red as 3.3 V and ground is brown, with the control line being orange. Generally, though, the 3.3 V is in the middle. Check the datasheet for your servo before wiring.

Fig. 670 Driving a servo motor with the 3.3 V power supply#

The code for controlling the servo motor is in servoMotor.py, shown

in Code for driving a servo motor (servoMotor.py).

1#!/usr/bin/env python

2# ////////////////////////////////////////

3# // servoMotor.py

4# // Drive a simple servo motor back and forth on P9_16 pin

5# // Wiring:

6# // Setup: config-pin P9_16 pwm

7# // See:

8# ////////////////////////////////////////

9import time

10import signal

11import sys

12

13pwmPeriod = '20000000' # Period in ns, (20 ms)

14pwm = '1' # pwm to use

15channel = 'b' # channel to use

16PWMPATH='/dev/bone/pwm/'+pwm+'/'+channel

17low = 0.8 # Smallest angle (in ms)

18hi = 2.4 # Largest angle (in ms)

19ms = 250 # How often to change position, in ms

20pos = 1.5 # Current position, about middle ms)

21step = 0.1 # Step size to next position

22

23def signal_handler(sig, frame):

24 print('Got SIGINT, turning motor off')

25 f = open(PWMPATH+'/enable', 'w')

26 f.write('0')

27 f.close()

28 sys.exit(0)

29signal.signal(signal.SIGINT, signal_handler)

30print('Hit ^C to stop')

31

32f = open(PWMPATH+'/period', 'w')

33f.write(pwmPeriod)

34f.close()

35f = open(PWMPATH+'/enable', 'w')

36f.write('1')

37f.close()

38

39f = open(PWMPATH+'/duty_cycle', 'w')

40while True:

41 pos += step # Take a step

42 if(pos > hi or pos < low):

43 step *= -1

44 duty_cycle = str(round(pos*1000000)) # Convert ms to ns

45 # print('pos = ' + str(pos) + ' duty_cycle = ' + duty_cycle)

46 f.seek(0)

47 f.write(duty_cycle)

48 time.sleep(ms/1000)

49

50# | Pin | pwm | channel

51# | P9_31 | 0 | a

52# | P9_29 | 0 | b

53# | P9_14 | 1 | a

54# | P9_16 | 1 | b

55# | P8_19 | 2 | a

56# | P8_13 | 2 | b

1#!/usr/bin/env node

2////////////////////////////////////////

3// servoMotor.js

4// Drive a simple servo motor back and forth on P9_16 pin

5// Wiring:

6// Setup: config-pin P9_16 pwm

7// See:

8////////////////////////////////////////

9const fs = require("fs");

10

11const pwmPeriod = '20000000'; // Period in ns, (20 ms)

12const pwm = '1'; // pwm to use

13const channel = 'b'; // channel to use

14const PWMPATH='/dev/bone/pwm/'+pwm+'/'+channel;

15const low = 0.8, // Smallest angle (in ms)

16 hi = 2.4, // Largest angle (in ms)

17 ms = 250; // How often to change position, in ms

18var pos = 1.5, // Current position, about middle ms)

19 step = 0.1; // Step size to next position

20

21console.log('Hit ^C to stop');

22fs.writeFileSync(PWMPATH+'/period', pwmPeriod);

23fs.writeFileSync(PWMPATH+'/enable', '1');

24

25var timer = setInterval(sweep, ms);

26

27// Sweep from low to hi position and back again

28function sweep() {

29 pos += step; // Take a step

30 if(pos > hi || pos < low) {

31 step *= -1;

32 }

33 var dutyCycle = parseInt(pos*1000000); // Convert ms to ns

34 // console.log('pos = ' + pos + ' duty cycle = ' + dutyCycle);

35 fs.writeFileSync(PWMPATH+'/duty_cycle', dutyCycle);

36}

37

38process.on('SIGINT', function() {

39 console.log('Got SIGINT, turning motor off');

40 clearInterval(timer); // Stop the timer

41 fs.writeFileSync(PWMPATH+'/enable', '0');

42});

43

44// | Pin | pwm | channel

45// | P9_31 | 0 | a

46// | P9_29 | 0 | b

47// | P9_14 | 1 | a

48// | P9_16 | 1 | b

49// | P8_19 | 2 | a

50// | P8_13 | 2 | b

You need to configure the pin for PWM.

bone$ cd ~/beaglebone-cookbook-code/04motors

bone$ config-pin P9_16 pwm

bone$ ./servoMotor.py

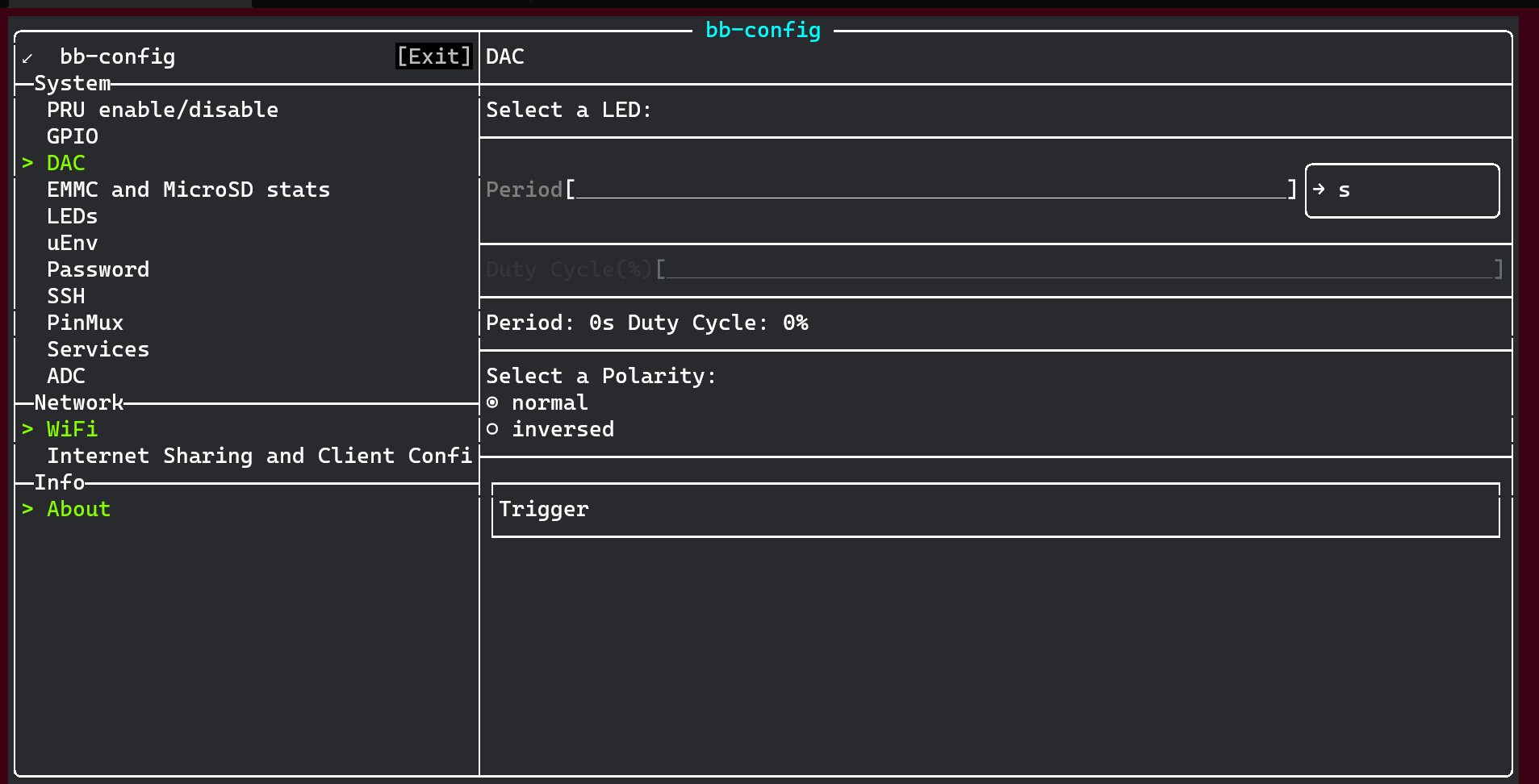

Configuring the PWM on the BeagleY-AI takes a little more effort than on the Bone. First select which PWM you want to use. https://pinout.beagleboard.io/pinout/pwm shows you have many to choose from.

Fig. 671 BeagleY-AI PWMs#

Let’s use PWM0 on GPIO12. Note this is Hat pin 32 as shown in the figure (hat-32). The instructions at Pulse Width Modulation (PWM) give details on how to configure the PWM pin. A shorter version is given here.

To enable any of the PWM Pins, we have to modify the file: /boot/firmware/extlinux/extlinux.conf. We can check the available list of Device Tree Overlays using the command:

debian@BeagleBone:~$ ls /boot/firmware/overlays/ | grep "beagley-ai-pwm"

k3-am67a-beagley-ai-pwm-ecap0-gpio12.dtbo

k3-am67a-beagley-ai-pwm-ecap1-gpio16.dtbo

k3-am67a-beagley-ai-pwm-ecap1-gpio21.dtbo

...

Add the line shown below to /boot/firmware/extlinux/extlinux.conf to load the gpio12 pwm device tree overlay:

fdtoverlays /overlays/k3-am67a-beagley-ai-pwm-epwm0-ecap0-gpio12.dtbo

Your /boot/firmware/extlinux/extlinux.conf file should look something like:

label microSD (default)

kernel /Image

append console=ttyS2,115200n8 root=/dev/mmcblk1p3 ro rootfstype=ext4 resume=/dev/mmcblk1p2 rootwait net.ifnames=0 quiet

fdtdir /

fdt /ti/k3-am67a-beagley-ai.dtb

fdtoverlays /overlays/k3-am67a-beagley-ai-pwm-ecap0-gpio12.dtbo

initrd /initrd.img

Now reboot you BeagleY-AI to load the overlay:

beagle$ sudo reboot

To configure HAT pin32 (GPIO12) PWM symlink pin using beagle-pwm-export execute the command below,

beagle$ sudo beagle-pwm-export --pin hat-32

We’ve changed the PWM pin that’s being used so we need to modfiy servoMotor.py.

Around line 16 you will see:

PWMPATH=’/dev/bone/pwm/’+pwm+’/’+channel

Change it to:

PWMPATH=’/dev/hat/pwm/GPIO12’

Now run your code:

beagle$ ./servoMotor.py

Running the code causes the motor to move back and forth, progressing to successive positions between the two extremes. You will need to press ^C (Ctrl-C) to stop the script.

Controlling a Servo with an Rotary Encoder#

Problem#

You have a rotary encoder from from chapter 2 rotary encoder example that you want to use to control a servo motor.

Solution#

Combine the code from rotaryEncoder.js and servoMotor.js.

bone$ config-pin P9_16 pwm

bone$ config-pin P8_11 eqep

bone$ config-pin P8_12 eqep

bone$ ./servoEncoder.py

1#!/usr/bin/env python

2# ////////////////////////////////////////

3# // servoEncoder.py

4# // Drive a simple servo motor using rotary encoder viq eQEP

5# // Wiring: Servo on P9_16, rotary encoder on P8_11 and P8_12

6# // Setup: config-pin P9_16 pwm

7# // config-pin P8_11 eqep

8# // config-pin P8_12 eqep

9# // See:

10# ////////////////////////////////////////

11import time

12import signal

13import sys

14

15# Set up encoder

16eQEP = '2'

17COUNTERPATH = '/dev/bone/counter/counter'+eQEP+'/count0'

18maxCount = '180'

19

20ms = 100 # Time between samples in ms

21

22# Set the eEQP maximum count

23fQEP = open(COUNTERPATH+'/ceiling', 'w')

24fQEP.write(maxCount)

25fQEP.close()

26

27# Enable

28fQEP = open(COUNTERPATH+'/enable', 'w')

29fQEP.write('1')

30fQEP.close()

31

32fQEP = open(COUNTERPATH+'/count', 'r')

33

34# Set up servo

35pwmPeriod = '20000000' # Period in ns, (20 ms)

36pwm = '1' # pwm to use

37channel = 'b' # channel to use

38PWMPATH='/dev/bone/pwm/'+pwm+'/'+channel

39low = 0.6 # Smallest angle (in ms)

40hi = 2.5 # Largest angle (in ms)

41ms = 250 # How often to change position, in ms

42pos = 1.5 # Current position, about middle ms)

43step = 0.1 # Step size to next position

44

45def signal_handler(sig, frame):

46 print('Got SIGINT, turning motor off')

47 f = open(PWMPATH+'/enable', 'w')

48 f.write('0')

49 f.close()

50 sys.exit(0)

51signal.signal(signal.SIGINT, signal_handler)

52

53f = open(PWMPATH+'/period', 'w')

54f.write(pwmPeriod)

55f.close()

56f = open(PWMPATH+'/duty_cycle', 'w')

57f.write(str(round(int(pwmPeriod)/2)))

58f.close()

59f = open(PWMPATH+'/enable', 'w')

60f.write('1')

61f.close()

62

63print('Hit ^C to stop')

64

65olddata = -1

66while True:

67 fQEP.seek(0)

68 data = fQEP.read()[:-1]

69 # Print only if data changes

70 if data != olddata:

71 olddata = data

72 # print("data = " + data)

73 # # map 0-180 to low-hi

74 duty_cycle = -1*int(data)*(hi-low)/180.0 + hi

75 duty_cycle = str(int(duty_cycle*1000000)) # Convert from ms to ns

76 # print('duty_cycle = ' + duty_cycle)

77 f = open(PWMPATH+'/duty_cycle', 'w')

78 f.write(duty_cycle)

79 f.close()

80 time.sleep(ms/1000)

81

82# Black OR Pocket

83# eQEP0: P9.27 and P9.42 OR P1_33 and P2_34

84# eQEP1: P9.33 and P9.35

85# eQEP2: P8.11 and P8.12 OR P2_24 and P2_33

86

87# AI

88# eQEP1: P8.33 and P8.35

89# eQEP2: P8.11 and P8.12 or P9.19 and P9.41

90# eQEP3: P8.24 and P8.25 or P9.27 and P9.42

91

92# | Pin | pwm | channel

93# | P9_31 | 0 | a

94# | P9_29 | 0 | b

95# | P9_14 | 1 | a

96# | P9_16 | 1 | b

97# | P8_19 | 2 | a

98# | P8_13 | 2 | b

Controlling the Speed of a DC Motor#

Problem#

You have a DC motor (or a solenoid) and want a simple way to control its speed, but not the direction.

Solution#

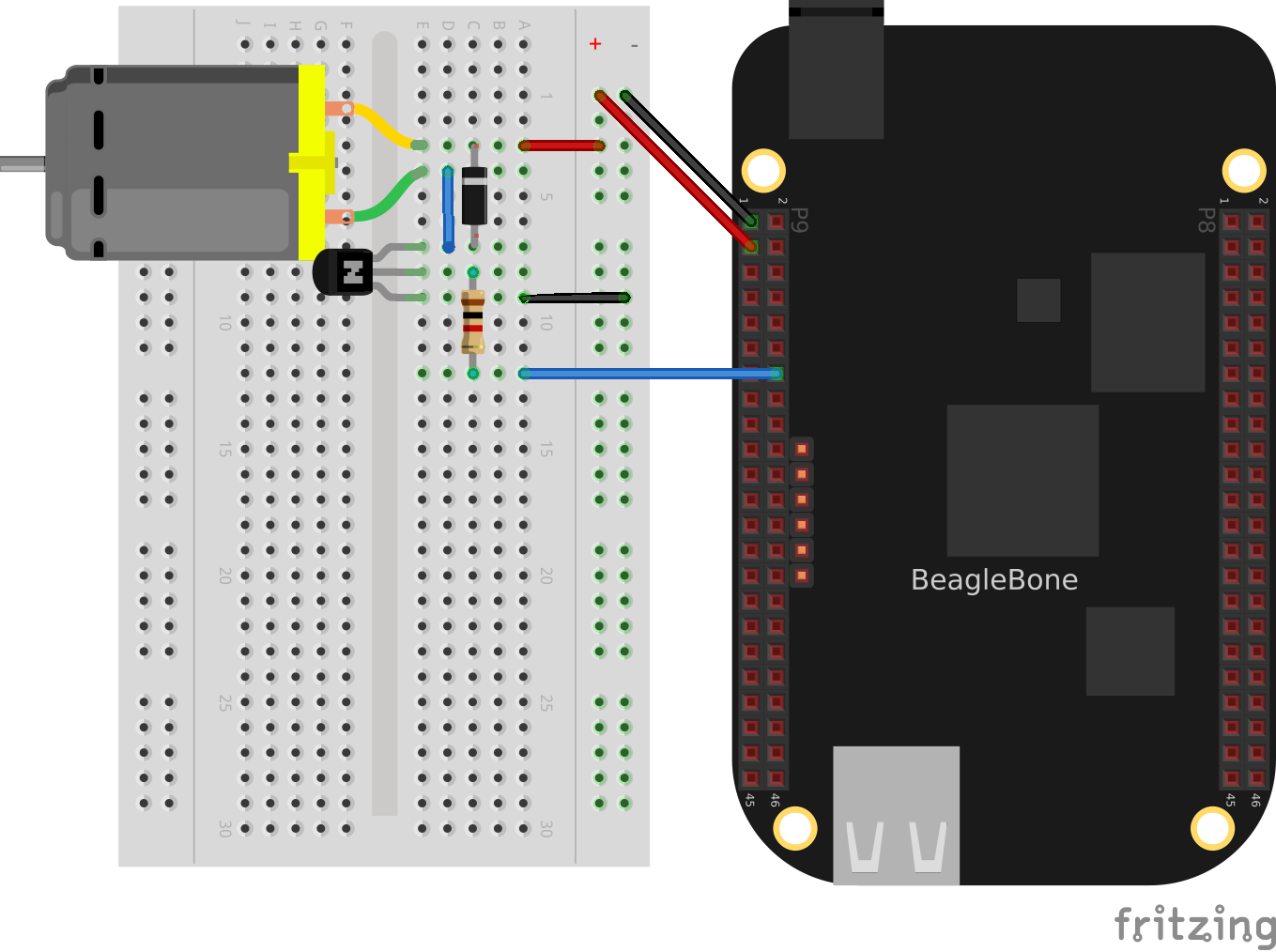

It would be nice if you could just wire the DC motor to BeagleBone Black and have it work, but it won’t. Most motors require more current than the GPIO ports on the Bone can supply. Our solution is to use a transistor to control the current to the bone.

Here we configure the encoder to returns value between 0 and 180 inclusive. This value is then mapped to a value between min (0.6 ms) and max (2.5 ms). This number is converted from milliseconds and nanoseconds (time 1000000) and sent to the servo motor via the pwm.

Here’s what you will need:

3 V to 5 V DC motor

Breadboard and jumper wires.

1 kΩ resistor.

Transistor 2N3904.

Diode 1N4001.

Power supply for the motor (optional)

If you are using a larger motor (more current), you will need to use a larger transistor.

Wire your breadboard as shown in Wiring a DC motor to spin one direction.

Fig. 672 Wiring a DC motor to spin one direction#

Use the code in Driving a DC motor in one direction (dcMotor.py) to run the motor.

1#!/usr/bin/env python

2# ////////////////////////////////////////

3# // dcMotor.js

4# // This is an example of driving a DC motor

5# // Wiring:

6# // Setup: config-pin P9_16 pwm

7# // See:

8# ////////////////////////////////////////

9import time

10import signal

11import sys

12

13def signal_handler(sig, frame):

14 print('Got SIGINT, turning motor off')

15 f = open(PWMPATH+'/enable', 'w')

16 f.write('0')

17 f.close()

18 sys.exit(0)

19signal.signal(signal.SIGINT, signal_handler)

20

21pwmPeriod = '1000000' # Period in ns

22pwm = '1' # pwm to use

23channel = 'b' # channel to use

24PWMPATH='/dev/bone/pwm/'+pwm+'/'+channel

25

26low = 0.05 # Slowest speed (duty cycle)

27hi = 1 # Fastest (always on)

28ms = 100 # How often to change speed, in ms

29speed = 0.5 # Current speed

30step = 0.05 # Change in speed

31

32f = open(PWMPATH+'/duty_cycle', 'w')

33f.write('0')

34f.close()

35f = open(PWMPATH+'/period', 'w')

36f.write(pwmPeriod)

37f.close()

38f = open(PWMPATH+'/enable', 'w')

39f.write('1')

40f.close()

41

42f = open(PWMPATH+'/duty_cycle', 'w')

43while True:

44 speed += step

45 if(speed > hi or speed < low):

46 step *= -1

47 duty_cycle = str(round(speed*1000000)) # Convert ms to ns

48 f.seek(0)

49 f.write(duty_cycle)

50 time.sleep(ms/1000)

1#!/usr/bin/env node

2////////////////////////////////////////

3// dcMotor.js

4// This is an example of driving a DC motor

5// Wiring:

6// Setup: config-pin P9_16 pwm

7// See:

8////////////////////////////////////////

9const fs = require("fs");

10

11const pwmPeriod = '1000000'; // Period in ns

12const pwm = '1'; // pwm to use

13const channel = 'b'; // channel to use

14const PWMPATH='/dev/bone/pwm/'+pwm+'/'+channel;

15

16const low = 0.05, // Slowest speed (duty cycle)

17 hi = 1, // Fastest (always on)

18 ms = 100; // How often to change speed, in ms

19var speed = 0.5, // Current speed;

20 step = 0.05; // Change in speed

21

22// fs.writeFileSync(PWMPATH+'/export', pwm); // Export the pwm channel

23// Set the period in ns, first 0 duty_cycle,

24fs.writeFileSync(PWMPATH+'/duty_cycle', '0');

25fs.writeFileSync(PWMPATH+'/period', pwmPeriod);

26fs.writeFileSync(PWMPATH+'/duty_cycle', pwmPeriod/2);

27fs.writeFileSync(PWMPATH+'/enable', '1');

28

29timer = setInterval(sweep, ms);

30

31function sweep() {

32 speed += step;

33 if(speed > hi || speed < low) {

34 step *= -1;

35 }

36 fs.writeFileSync(PWMPATH+'/duty_cycle', parseInt(pwmPeriod*speed));

37 // console.log('speed = ' + speed);

38}

39

40process.on('SIGINT', function() {

41 console.log('Got SIGINT, turning motor off');

42 clearInterval(timer); // Stop the timer

43 fs.writeFileSync(PWMPATH+'/enable', '0');

44});

See Also#

How do you change the direction of the motor? See Controlling the Speed and Direction of a DC Motor.

Controlling the Speed and Direction of a DC Motor#

Problem#

You would like your DC motor to go forward and backward.

Solution#

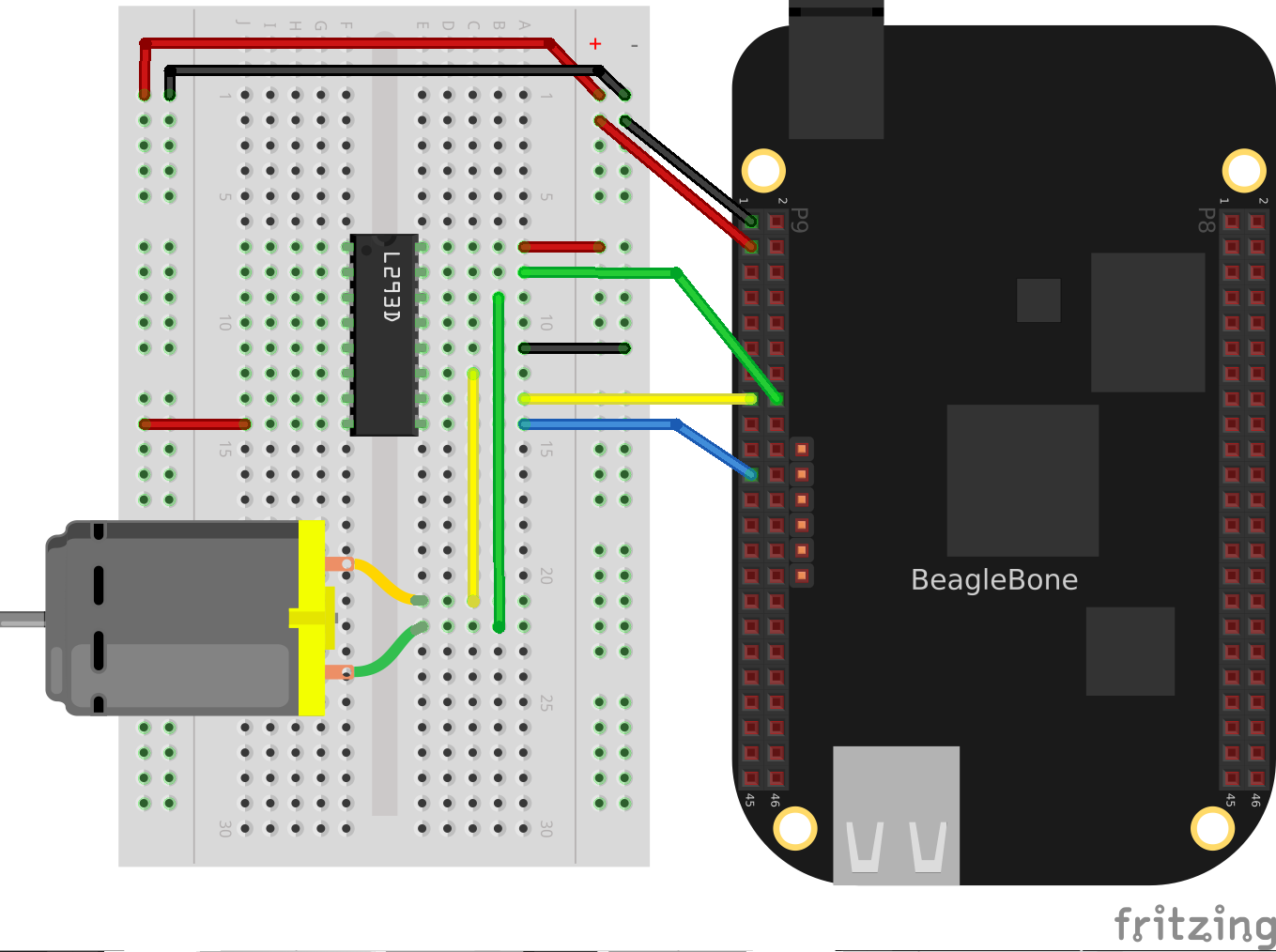

Use an H-bridge to switch the terminals on the motor so that it will run both backward

and forward. We’ll use the L293D a common, single-chip H-bridge.

Here’s what you will need:

3 V to 5 V motor.

Breadboard and jumper wires.

L293D H-Bridge IC.

Power supply for the motor (optional)

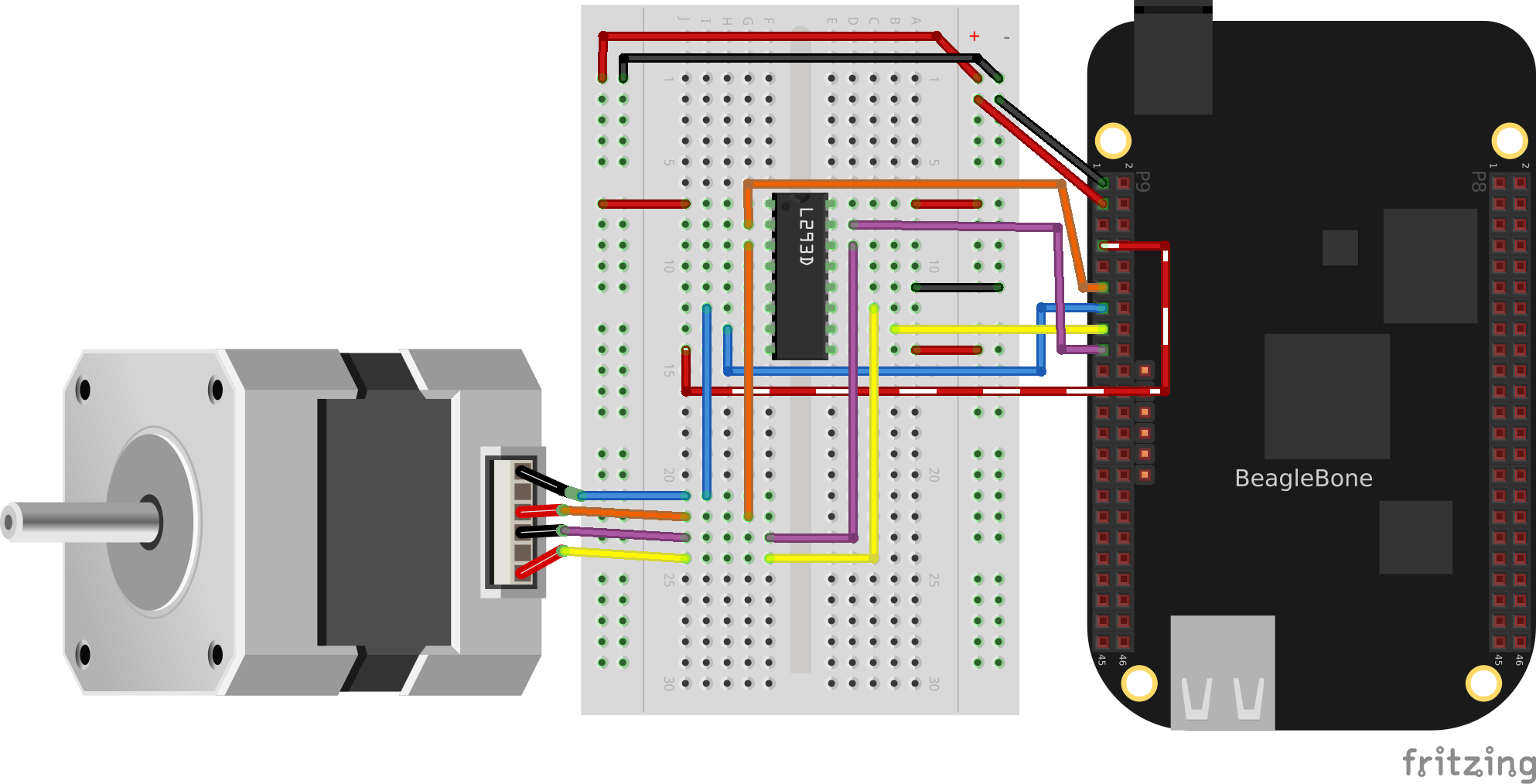

Lay out your breadboard as shown in Driving a DC motor with an H-bridge. Ensure that the L293D is positioned correctly. There is a notch on one end that should be pointed up.

Fig. 673 Driving a DC motor with an H-bridge#

The code in Code for driving a DC motor with an H-bridge (h-bridgeMotor.js) (h-bridgeMotor.js) looks much like the code for driving the DC

motor with a transistor (Driving a DC motor in one direction (dcMotor.js)). The additional code specifies which direction to spin the motor.

1#!/usr/bin/env node

2

3// This example uses an H-bridge to drive a DC motor in two directions

4

5var b = require('bonescript');

6

7var enable = 'P9_21'; // Pin to use for PWM speed control

8 in1 = 'P9_15',

9 in2 = 'P9_16',

10 step = 0.05, // Change in speed

11 min = 0.05, // Min duty cycle

12 max = 1.0, // Max duty cycle

13 ms = 100, // Update time, in ms

14 speed = min; // Current speed;

15

16b.pinMode(enable, b.ANALOG_OUTPUT, 6, 0, 0, doInterval);

17b.pinMode(in1, b.OUTPUT);

18b.pinMode(in2, b.OUTPUT);

19

20function doInterval(x) {

21 if(x.err) {

22 console.log('x.err = ' + x.err);

23 return;

24 }

25 timer = setInterval(sweep, ms);

26}

27

28clockwise(); // Start by going clockwise

29

30function sweep() {

31 speed += step;

32 if(speed > max || speed < min) {

33 step *= -1;

34 step>0 ? clockwise() : counterClockwise();

35 }

36 b.analogWrite(enable, speed);

37 console.log('speed = ' + speed);

38}

39

40function clockwise() {

41 b.digitalWrite(in1, b.HIGH);

42 b.digitalWrite(in2, b.LOW);

43}

44

45function counterClockwise() {

46 b.digitalWrite(in1, b.LOW);

47 b.digitalWrite(in2, b.HIGH);

48}

49

50process.on('SIGINT', function() {

51 console.log('Got SIGINT, turning motor off');

52 clearInterval(timer); // Stop the timer

53 b.analogWrite(enable, 0); // Turn motor off

54});

Driving a Bipolar Stepper Motor#

Problem#

You want to drive a stepper motor that has four wires.

Solution#

Use an L293D H-bridge. The bipolar stepper motor requires us to reverse the coils, so we need to use an H-bridge.

Here’s what you will need:

Breadboard and jumper wires.

3 V to 5 V bipolar stepper motor.

L293D H-Bridge IC.

Wire as shown in Bipolar stepper motor wiring.

Fig. 674 Bipolar stepper motor wiring#

Use the code in Driving a bipolar stepper motor (bipolarStepperMotor.py) to drive the motor.

1#!/usr/bin/env python

2import time

3import os

4import signal

5import sys

6

7# Motor is attached here

8# controller = ["P9_11", "P9_13", "P9_15", "P9_17"];

9# controller = ["30", "31", "48", "5"]

10# controller = ["P9_14", "P9_16", "P9_18", "P9_22"];

11controller = ["50", "51", "4", "2"]

12states = [[1,0,0,0], [0,1,0,0], [0,0,1,0], [0,0,0,1]]

13statesHiTorque = [[1,1,0,0], [0,1,1,0], [0,0,1,1], [1,0,0,1]]

14statesHalfStep = [[1,0,0,0], [1,1,0,0], [0,1,0,0], [0,1,1,0],

15 [0,0,1,0], [0,0,1,1], [0,0,0,1], [1,0,0,1]]

16

17curState = 0 # Current state

18ms = 100 # Time between steps, in ms

19maxStep = 22 # Number of steps to turn before turning around

20minStep = 0 # minimum step to turn back around on

21

22CW = 1 # Clockwise

23CCW = -1

24pos = 0 # current position and direction

25direction = CW

26GPIOPATH="/sys/class/gpio"

27

28def signal_handler(sig, frame):

29 print('Got SIGINT, turning motor off')

30 for i in range(len(controller)) :

31 f = open(GPIOPATH+"/gpio"+controller[i]+"/value", "w")

32 f.write('0')

33 f.close()

34 sys.exit(0)

35signal.signal(signal.SIGINT, signal_handler)

36print('Hit ^C to stop')

37

38def move():

39 global pos

40 global direction

41 global minStep

42 global maxStep

43 pos += direction

44 print("pos: " + str(pos))

45 # Switch directions if at end.

46 if (pos >= maxStep or pos <= minStep) :

47 direction *= -1

48 rotate(direction)

49

50# This is the general rotate

51def rotate(direction) :

52 global curState

53 global states

54 # print("rotate(%d)", direction);

55 # Rotate the state according to the direction of rotation

56 curState += direction

57 if(curState >= len(states)) :

58 curState = 0;

59 elif(curState<0) :

60 curState = len(states)-1

61 updateState(states[curState])

62

63# Write the current input state to the controller

64def updateState(state) :

65 global controller

66 print(state)

67 for i in range(len(controller)) :

68 f = open(GPIOPATH+"/gpio"+controller[i]+"/value", "w")

69 f.write(str(state[i]))

70 f.close()

71

72# Initialize motor control pins to be OUTPUTs

73for i in range(len(controller)) :

74 # Make sure pin is exported

75 if (not os.path.exists(GPIOPATH+"/gpio"+controller[i])):

76 f = open(GPIOPATH+"/export", "w")

77 f.write(pin)

78 f.close()

79 # Make it an output pin

80 f = open(GPIOPATH+"/gpio"+controller[i]+"/direction", "w")

81 f.write("out")

82 f.close()

83

84# Put the motor into a known state

85updateState(states[0])

86rotate(direction)

87

88# Rotate

89while True:

90 move()

91 time.sleep(ms/1000)

When you run the code, the stepper motor will rotate back and forth.

Driving a Unipolar Stepper Motor#

Problem#

You want to drive a stepper motor that has five or six wires.

Solution#

If your stepper motor has five or six wires, it’s a unipolar stepper and

is wired differently than the bipolar. Here, we’ll use

a ULN2003 Darlington Transistor Array IC to drive the motor.

Here’s what you will need:

Breadboard and jumper wires.

3 V to 5 V unipolar stepper motor.

ULN2003 Darlington Transistor Array IC.

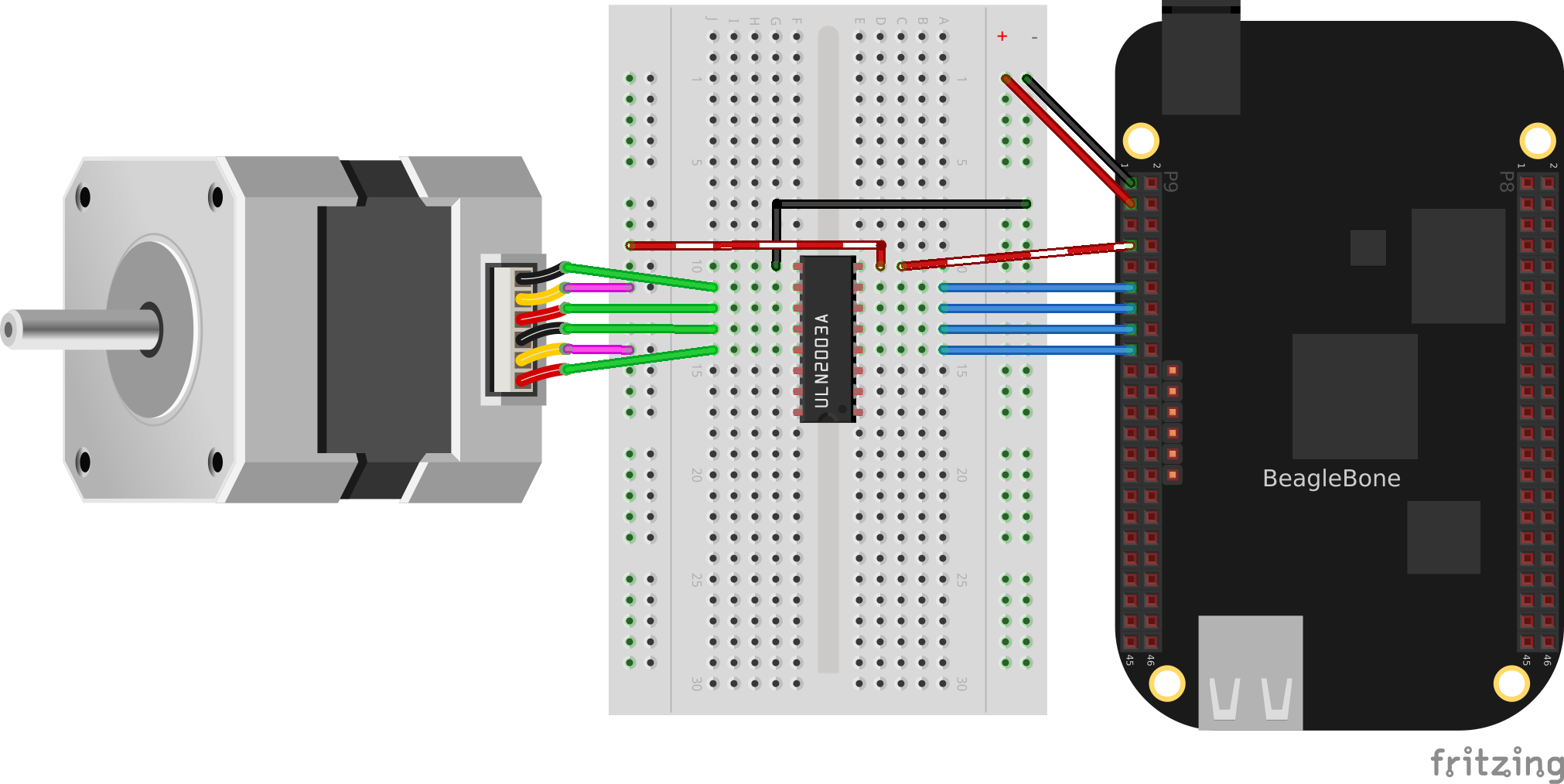

Wire, as shown in Unipolar stepper motor wiring.

Note

The IC in Unipolar stepper motor wiring is illustrated upside down from the way it is usually displayed.

That is, the notch for pin 1 is on the bottom. This made drawing the diagram much cleaner.

Also, notice the banded wire running the P9_7 (5 V) to the UL2003A.

The stepper motor I’m using runs better at 5 V, so I’m using the Bone’s 5 V power supply.

The signal coming from the GPIO pins is 3.3 V, but the U2003A will step them up to 5 V to drive

the motor.

Fig. 675 Unipolar stepper motor wiring#

The code for driving the motor is in unipolarStepperMotor.js however, it is

almost identical to the bipolar stepper code (Driving a bipolar stepper motor (bipolarStepperMotor.py)),

so Changes to bipolar code to drive a unipolar stepper motor (unipolarStepperMotor.js.diff) shows only the lines that you need to change.

1# controller = ["P9_11", "P9_13", "P9_15", "P9_17"]

2controller = ["30", "31", "48", "5"]

3states = [[1,1,0,0], [0,1,1,0], [0,0,1,1], [1,0,0,1]]

4curState = 0 // Current state

5ms = 100 // Time between steps, in ms

6max = 200 // Number of steps to turn before turning around

1# var controller = ["P9_11", "P9_13", "P9_15", "P9_17"];

2controller = ["30", "31", "48", "5"]

3var states = [[1,1,0,0], [0,1,1,0], [0,0,1,1], [1,0,0,1]];

4var curState = 0; // Current state

5var ms = 100, // Time between steps, in ms

6 max = 200, // Number of steps to turn before turning around

The code in this example makes the following changes:

The states are different. Here, we have two pins high at a time.

The time between steps (ms) is shorter, and the number of steps per direction (max) is bigger. The unipolar stepper I’m using has many more steps per rotation, so I need more steps to make it go around.